Since 2019, AICA has been focused on developing intuitive robotics software that enables engineers to automate complex robotics tasks. On October 10th 2024, we reach a major milestone: the first public release of the AICA System!

About AICA System & Studio

- Interactive application builder

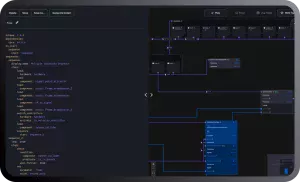

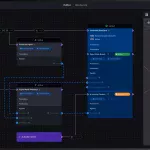

- AICA Studio lets you build advanced robotic applications more easily than ever with our unique drag-and-drop graph editor

- Real-time control and monitoring

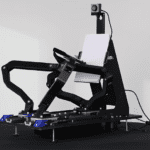

- Connect to industry standard robot arms with advanced position, velocity, and force controllers

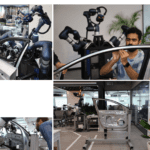

- Motion generation and reinforcement learning

- Access a growing library of smart components, or extend the functionality with our open SDK

Why choose AICA System?

As an innovative software startup, AICA is developing new ways to control robots to make them more generalizable and adaptable to different tasks. The ability to deploy real-time, sensor-driven control loops on robot platforms is becoming increasingly important. With a focus on modern, modular software development and a strong foundation in machine learning and optimization techniques, you can explore new ways to advance your projects in this field.

Brand new features in AICA Studio v4.0

- Live visualization

- Monitor robot and sensor state data directly in the browser

- Manage application events

- A new transition event feature allows precise management of lifecycle states and error handling for components, controllers and hardware

- Advanced application logic

- Use the new sequence and condition blocks to define exactly where and when application events should occur

For more information about the product and AICA, visit the company’s website: https://www.aica.tech/blog/product-launch