AICA Reaches Key Milestone in Project LAMBDA With Successful EV Battery Disassembly

AICA has reached a key milestone in Project LAMBDA through collaboration with Circu Li-ion and the Swiss Battery Technology Center (SBTC). Together, the partners successfully disassembled a high-voltage electric vehicle […]

New implant restores pressure balance after spinal cord injury

A groundbreaking new implant is giving people with spinal cord injuries a chance to regain control over their lives. Developed by EPFL’s Grégoire Courtine and UNIL/CHUV’s Jocelyne Bloch, the system […]

Surgical Robotics, A curated analysis

Enjoy navigating a free and resourceful website on surgical robots. Interactive, rich, dynamic entry-point to all useful information, this platform lets you review and search complete data sheets about surgical […]

Advancing Mobile Robotics: ARM Laboratory’s robots designed for Inspections and Maintenance operations in Harsh Environments

In the demanding world of industrial maintenance, human operators routinely confront hazardous conditions while performing dangerous tasks in confined, elevated, or degraded environments. The maintenance industry requires systems that can […]

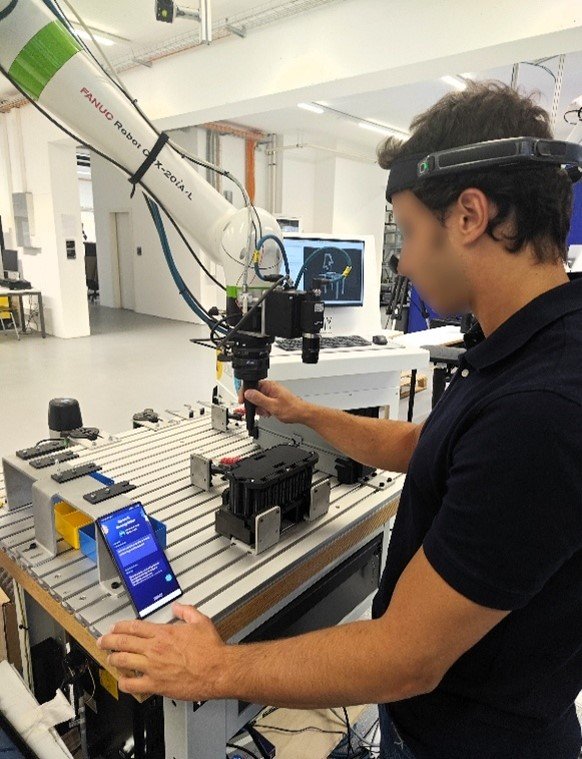

Robo-Gym. Smart Interface to Accelerate the Human-Robot Teamwork

In many industrial domains, full automation remains either technically infeasible, economically impractical, or too rigid to accommodate the diversity of real-world tasks and objects. In such contexts, cobots provide an […]

Four SNSF Advanced Grants go to ETH Zurich researchers

Four ETH Zurich professors have been awarded SNSF Advanced Grants, receiving a total of 8.5 million CHF over five years. These grants, ranging from 1.9 to 2.7 million CHF per […]